Adelco Screen Printing Machines: Versatile & Advanced Textile Solution

Our innovative screen printing equipment streamlines the process for direct-to-garment and t-shirt printing.

Revolutionising Garment and T-Shirt Screen Printing

Discover the exceptional range of Adelco's screen printing machines, engineered to redefine the process for direct-to-garment and t-shirt printing. Our innovative equipment caters to a diverse array of UK businesses, from independent designers to large textile manufacturers, offering efficient, economical, and superior printing solutions.

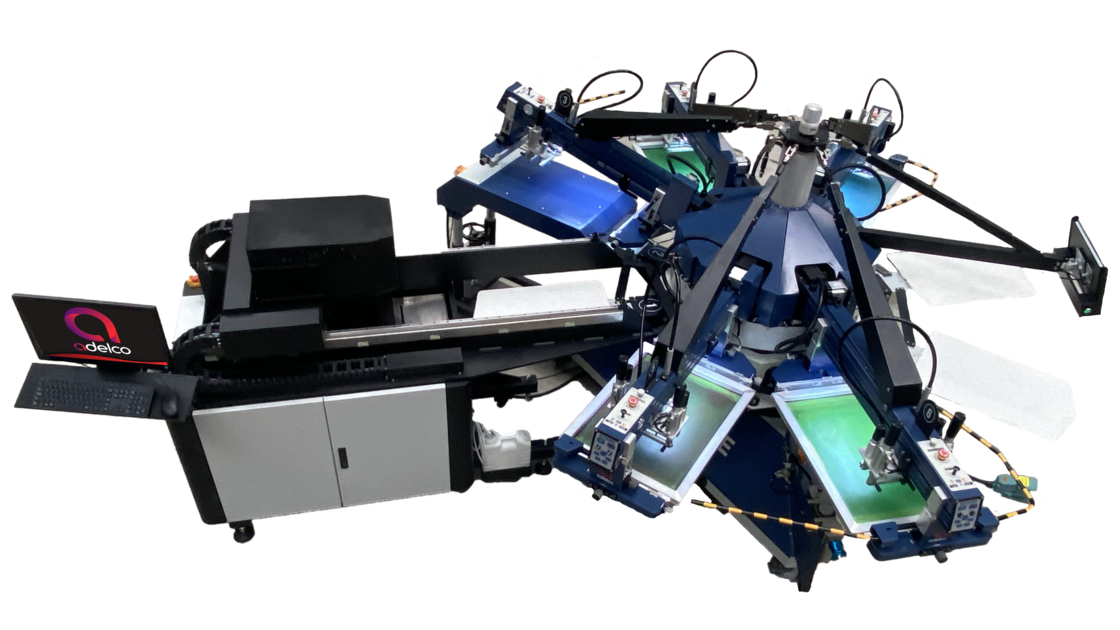

Adelco Hybrid Digital II

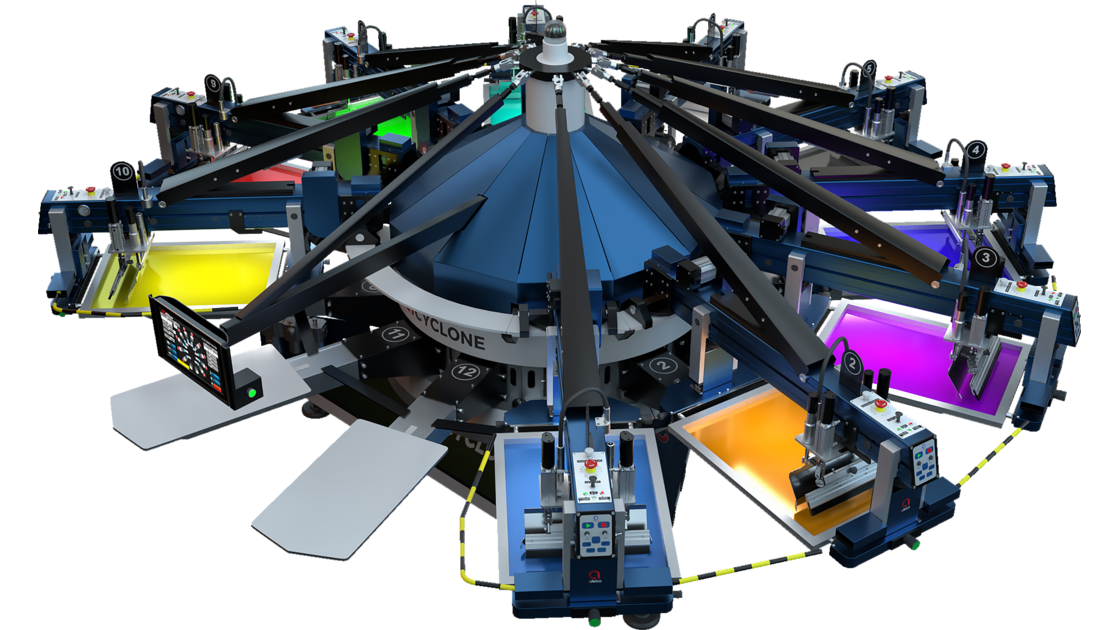

Adelco Cyclone

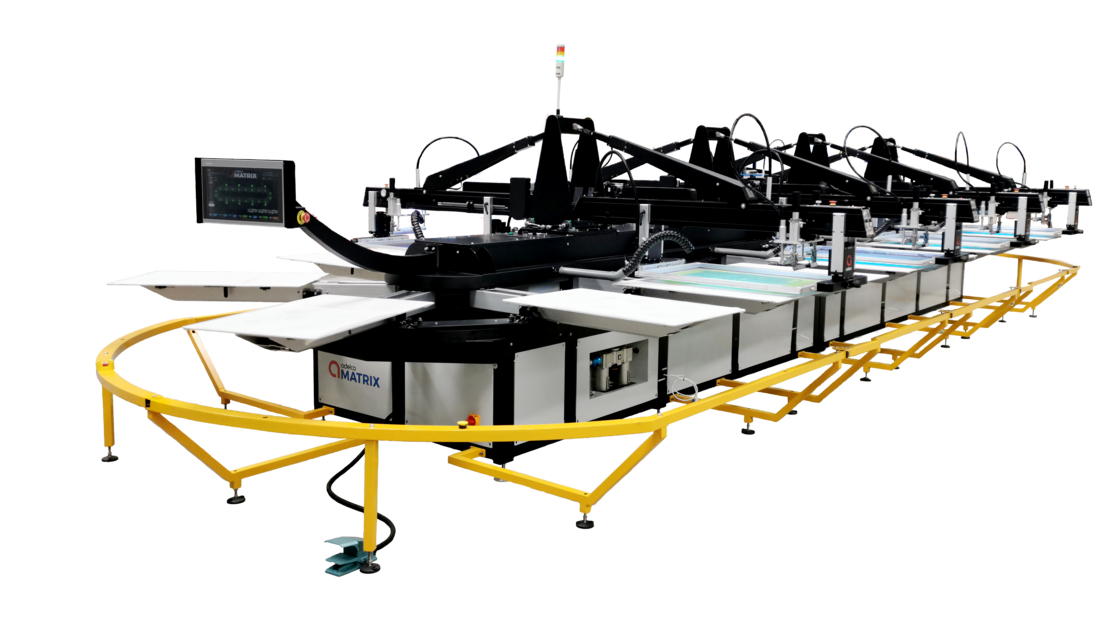

Adelco Matrix Oval Screen Printer

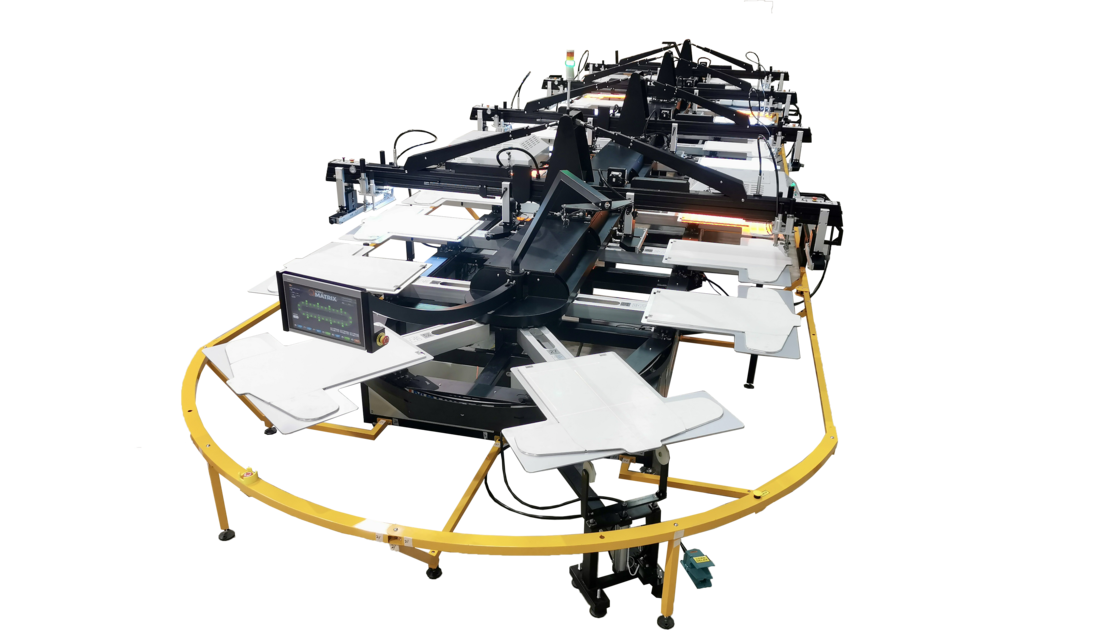

Adelco Ellipse Oval

Adelco Ellipse Sock Oval

Adelco All Over Oval

Universal Flash Cure

Hot Air Flash Cure

Exploring Screen Printing: A Fusion of Art and Technology

Screen printing is an art form that requires skill and precision. The process involves pressing ink through a mesh screen onto fabric, each colour applied separately for complex designs. Ideal for larger production runs, screen printing offers a balance between vibrancy, durability, and cost-efficiency.

The Advantages of Screen Printing with Adelco

Opting for screen printing means choosing a method that ensures vibrant and long-lasting results. Particularly cost-effective for orders over 500 pieces, this method provides a tactile and visually appealing finish.

Addressing the Challenges of Screen Printing

We recognise the challenges inherent in screen printing, such as the need for skilled operation and significant space. Our solutions simplify these issues, providing user-friendly, space-efficient machines suitable for all skill levels.

All-Inclusive Support and Materials for Screen Printing

Your Complete Solution for Printing Excellence

Adelco offers more than just machines; we provide a full suite of solutions for screen printing. This includes advanced software, high-quality screen emulsions, drying racks, and comprehensive support, ensuring a seamless printing process.

FAQs: Your Guide to Screen Printing with Adelco

- How do Adelco's machines guarantee top-notch print quality?

-

Our machines are equipped with state-of-the-art technology, ensuring consistent precision and quality across various fabrics and designs. This advanced technology guarantees accurate registration and optimal ink application, resulting in vibrant, durable prints on a wide range of materials.

- Which screen printing machine is best for my business size?

-

Small Businesses or Startups Machines like the Adelco Cyclone offer incredible value for money, making them suitable for smaller operations.

Growing Businesses: Machines like the Adelco Hybrid Digital provide scalability and efficiency, accommodating increasing production demands.

Large Businesses: High-production machines such as the Adelco Ellipse Oval are designed to handle extensive workloads with speed and precision by expanding up to 52 stations.

- How many colours can your screen printing machines handle?

-

Adelco's machines are designed to handle multiple colours, offering flexibility to accommodate a range of colours depending on the specific configuration and needs of the user.

- Are Adelco screen printing machines compatible with all ink types?

-

Adelco machines are designed to work with a variety of ink types, including plastisol and water-based. It's essential to consult the specific machine's guidelines for compatibility and optimal performance.

- How much space is required for installation?

-

Space requirements vary by model. It's recommended to consult the specific machine's installation manual or contact Adelco's support team for detailed space and facility requirements - we will be happy to help.

- What support can I expect from Adelco after purchase?

-

Adelco is committed to providing comprehensive customer support, including post-purchase services such as maintenance assistance, operational training, and technical support, ensuring your machines continue to perform at their best.