T-Shirt & Sons - 2018

Extracts taken from Images Magazine - March 18

The new unit housing T Shirt & Son’s DTG operation, opened last year and is home to a vast, well-organised garment area that wouldn’t look out of place at a multi-brand distribution centre, 10 Kornit Avalanche printers in climate-controlled rooms, hulking Adelco dryers and numerous staff.

They moved to their current location on the west Wiltshire Trading Estate in Westbury 14 years ago. Starting out in a single unit, the business’s rapid growth over the last four years has seen it expand into five units spread across the estate, including the new 34,000sq ft DTG facility. As well as opening a second 15,000sq ft DTG facility housing a further six Kornit avalanches in the city of Venlo in the Netherlands.

The brothers first DTG printer was an Epson-based model from DTG Digital Europe.

One of our screen printing clients wanted a personalised project. It was really hard work, but it made us understand that something was going to happen here.

Andy, Director, T-Shirt & Sons, UK

The next purchase was a Kornit Breeze, which rapidly became three Breezes, then two Storms. Then in 2014, the big shift happened with the purchase of two Avalanches.

The current Avalanches, which were upgraded to R-series models in 2017, will be upgraded again this year to the HD-Series machines that were launched at the beginning of the year. Given that the company purchases 12 tonnes of ink a year, the 30% ink savings promised by the new HDs-one of which its currently beta testing – makes the upgrade a no-brainer.

The current line-up of 10 Avalanches in the UK and six in the Holland facility is sufficient to handle production… For now. The company knows what growth is needed in the next couple of years because its team carefully tracks the growth and prospects of its customers. And even without taking on any new customers in the next year, new machines will be required, with space already set aside in the new unit to accommodate them. The new machines will include a Kornit Vulcan, which is said to be capable of printing 250 shirts an hour.

It's an expensive machine – it’s a three-quarter of a million pound investment – but it does produce the numbers, and it gives you a crossover to screen print.

Andy, Director, T-Shirt & Sons, UK

The rapid growth achieved by T-shirt & Sons isn’t for the faint hearted either. Deciding to buy the two Avalanches in 2014 may have been a calculated risk but is still required sturdy nerves to get through the first few months. “It was terrifying,” admits Andy.

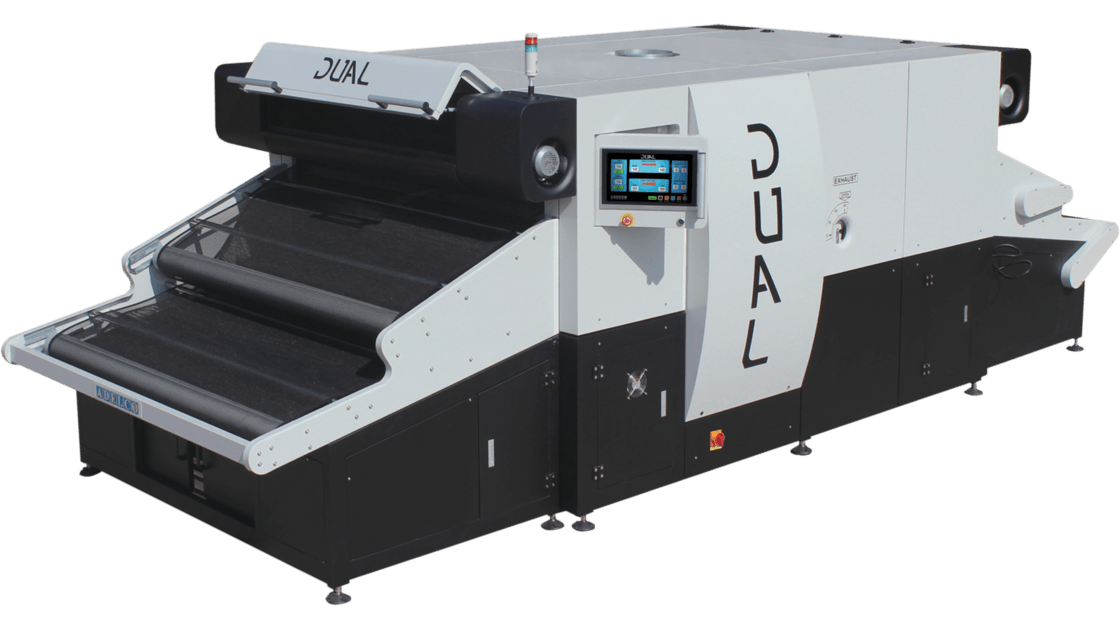

It was almost seven hundred grands worth of kit. And we needed a new dryer as well, so we bought an Adelco. Adelco are the best dryers by a country mile.

Mark and Leigh Smith have been in the industry a long time and are the only owner-owned manufacturer/distributors in the industry. They’ll look at what you need and will then create a solution for you, rather than trying to find a product to fit you. That makes a huge difference. We’ve got six Ecotexes now and three Duals. The Dual is amazing, you can get a huge volume of digital through a very small area. And Steve, who’s their main engineer, he’s just brilliant, he really knows these machines.

Andy, Director, T-Shirt & Sons, UK

Testimonial

The next purchase was a Kornit Breeze, which rapidly became three Breezes, then two Storms. Then in 2014, the big shift happened with the purchase of two Avalanches.

The current Avalanches, which were upgraded to R-series models in 2017, will be upgraded again this year to the HD-Series machines that were launched at the beginning of the year. Given that the company purchases 12 tonnes of ink a year, the 30% ink savings promised by the new HDs-one of which its currently beta testing – makes the upgrade a no-brainer.

The current line-up of 10 Avalanches in the UK and six in the Holland facility is sufficient to handle production… For now. The company knows what growth is needed in the next couple of years because its team carefully tracks the growth and prospects of its customers. And even without taking on any new customers in the next year, new machines will be required, with space already set aside in the new unit to accommodate them. The new machines will include a Kornit Vulcan, which is said to be capable of printing 250 shirts an hour.

My experience with Adelco has been fantastic and I would recommend Adelco and their products to anyone. I have known Mark a long time and consider him a friend more than just a business contact. He is someone we can trust, honest to his word, and if he says he is going to do something he does.

Jon Lunt, Director, TShirt & Sons, UK

Machines featured in this case study

Adelco Dual Dryer

Recent case studies

DTF Case Study - Fifth Column