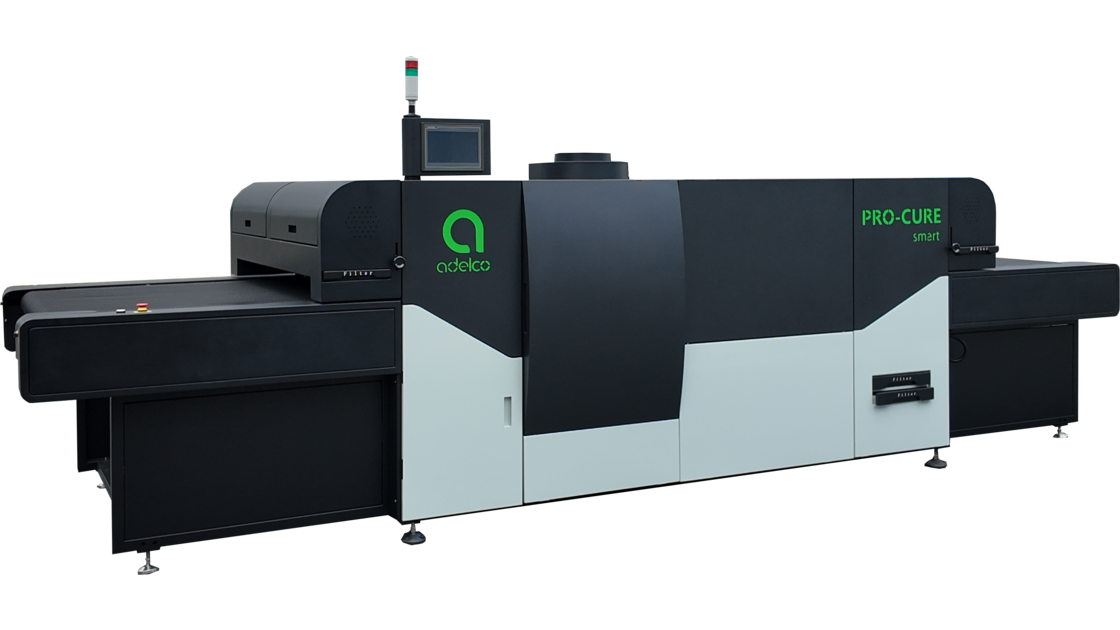

Key features of the Pro-Cure SMART

- Five conveyor belt widths available & limitless oven lengths - Modular in design

- Gas or Electric textile conveyor dryer

- Built in infeed and outfeed fume extraction system

- Self-tensioning, self-aligning conveyor belt with rubber covered rollers for unmatched belt life and tracking

- Ergonomically positioned and adjustable HDMI touch screen control panel interface.

- Reduced energy consumption, low running costs

- Easy to clean, service & maintain - fine filtration system

- Fast textile curing times for both digital and screen printed garments

- Easy to access Curing time and temperature records

- Triple insulation with air curtain for the coolest exterior skin.

- Split belt options

- Vacuum pull down

Adelco is like a family to me, Adelco Dryers have strong money back – Good return, the problem is that they are too good.

Pally Hayre, Pally, UK

Full features and advantages of the Adelco Pro-Cure SMART

- Various belt widths available: Split belt, 1m, 1.2m 1.5m & 1.8m

- Unlimited oven lengths available:

- Auto-tension, self-tracking rollers

- Available as a Gas or Electric conveyor dryer

- Easy to service & maintain with quick release panels & filters

- Digital automatic conveyor belt speed control

- Sophisticated touch-screen digital control panel interface

- Vaccum pulldown, providing exceptional stability of delicate fabrics, preventing lifting and flipping over.

- Unique Hood extraction, helps prevent fumes escaping, cleaner and fresher environment.

- Split belt options. Two burners, two speeds, two directions, two production lines.

- Triple insulation with air curtain for the coolest exterior skin.

- Integral exhaust adjustment

- High Air flow for increased penetration, leading to faster curing times and giving unrivalled heat distribution

- Reduced energy consumption for low running costs

- Highly efficient, direct Ultra-Violet controlled burner system

- Optional VOC exhaust filtration system

- Recycles clean filtered air and extracts contaminated air

- Optional Quartz pre-heat for temperature boost at oven entry

- Removable Lint filters from either side of the dryer, no replacement filters required.

- Fast and easy Filtration system that can be cleaned whilst the dryer is running, no replacement filters required.

Make an enquiry now

Register your interest in the Pro-Cure SMART now. We guarantee you won't be disappointed.